Organic Alfalfa Under Center Pivot Irrigation

Locale

The San Luis Valley in Colorado is classified as high-altitude true desert (less than 8” of annual precipitation). Our client’s operation is located in the vicinity of Alamosa, CO with average annual precipitation 7.31”. All agricultural operations in the ’Valley’ are irrigated; with the majority under center pivots. Typically, the water for center pivot supply is surface water run-off during the first 8 weeks of the growing season, then drawn from deep aquifer wells through-out the remainder of the year. Due to the demands on the aquifer water (source of water for Denver), the State and Federal governments have established a Water Control Department which has restricted the supply/usage by the agricultural operations to 50% of their historical levels. This has forced those operations to explore options that can “do more with less” and hence the involvement of AquAlign™ in their solution.

Our customer, K-C Farms, is an organic operation, and the owner is considered an expert in organic farming methodology with historical RFV numbers which have drawn the attention of multiple customers prepared to pay premium value for his crop. He employs the services of an agronomist consultant during each phase of his operation; measuring, assessing and adjusting his applications based on recommendations derived from hard data gathered at each stage of operation during the year.

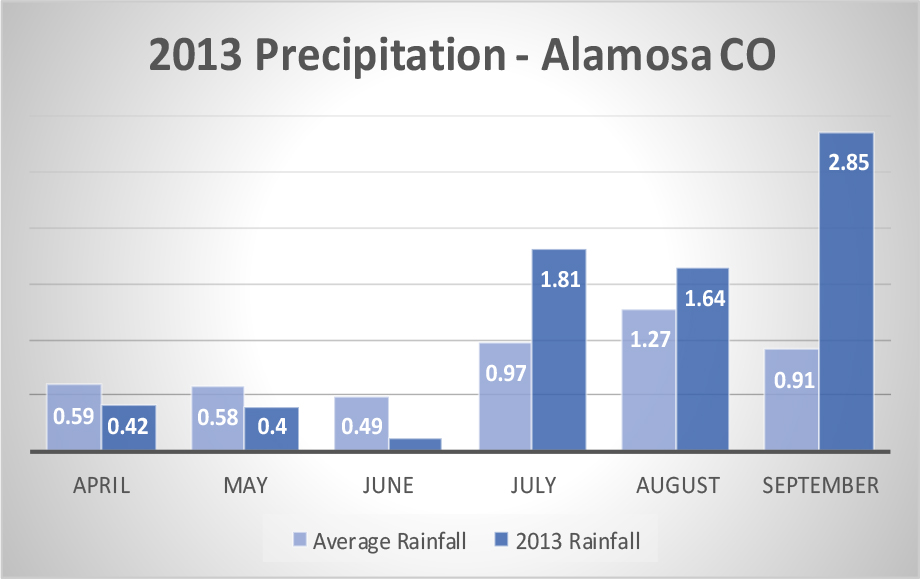

The precipitation levels in 2013 were in the first part of the growing season considered “low normal”. However during July, August and September rainfall was significantly higher than normal, impacting both the timing of cropping and the requirement to irrigate.

Synopsis of K-C Farms Operations

- Three cuts per season.

- The crop is cut at the early bud stage for highest quality.

- The alfalfa field is a total of 128 acres with 112 acres under direct central pivot irrigation (remainder via ‘gun’ irrigation), with a yield of approximately 3.78 tons per acre. This is considered “average or better” for organic alfalfa.

- K-C Farm’s historical reported average for Relative Food Value (RFV) is 200.

- In 2013, the field was in year 7 of an 8-10 year cycle wherein yield is generally reported to have dropped from optimal.

- Soil testing indicates low phosphorus levels to be augmented as prescribed, plus boron recommended.

- Compost has been added at the rate of 2-3 tons per acre annually for several years. Field capacity improved as a result of compost, (water retention ability of the soil).

- Augmentation with Epsom salts, plus 35% Hydrogen Peroxide is administered via pivot as required.

- The irrigation water allotment has been cut by 50%. Pivot modifications were made to optimize the water delivery reduced water loss through evaporation).

- Sheep are grazed on the land after the last cut each year, for weed control and a natural addition of fertilizer.

Stated Objectives

- Maintain or improve yield in the face of reduced irrigation.

- Maintain or improve nutritional valuation.

- Ultimately to attain a 4th cutting weather permitting.

Demonstration Protocol

Zone 2 and 3 of the Pivot’s circumference were chosen as the Test Site. Zone 2 would have an AquAlign™ unit on every drop, while Zone 3 on every other drop. The total area of these two zones roughly equates to the area of Zone 4 which was identified as the Control. Either a BRIX (field test that relates to sugar content) or a tissue sample analysis was done at each cutting for both the test zones and the control.

Results:

The season began with weather typical of the semi-arid region and rainfall in the normal low range.

Cut 1

The first cut was July 5th, the visual inspection of the test vs control revealed no difference in color, height, weed pressure or density, however the % bloom in Zone 2 was 7% versus 3% in Control Zone.

The BRIX results (based on 10 random measurements) were:

Control: 7 Test 3 (every other drop): 10 Test 2 (every drop): 23

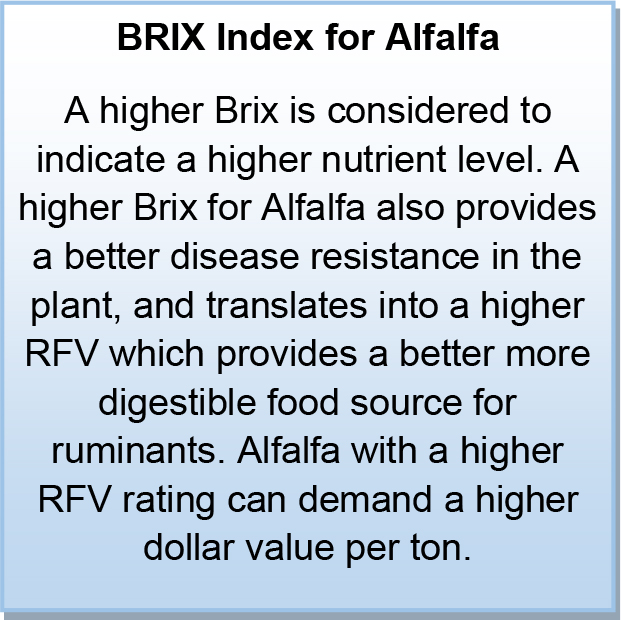

Our customer was amazed by a BRIX of 23, since the highest alfalfa BRIX on record (to our customer’s knowledge) in the San Luis Valley was 15!

Cut 2

Immediately after the first cut (July 7th) an unusual amount of rain for the region started to fall and continued for most of July and into August. This resulted in there being no need to irrigate for over a month, and hence no delivery of the AquAlign™ treatment to the crop. The second cutting (Aug 23) occurred about 4 weeks late due to the wet weather. As such the bloom was significant across the crop (15-20%). Typically the greater the bloom the lower the RFV quality however the trade-off is usually that the quantity of yield is higher.

Tissue samples were taken with the following results:

Control: RFV 169 (Good Grade)Test 2: RFV 178 (Premium Grade)

Relative Forage Quality 171Relative Forage Quality 181

In general the AquAlign™ test results showed higher mineral and protein content, a 3.39% lower lignin content but a 6.25% higher fat content. The observation was that despite the prolonged rain and lack of need to irrigate, the impact of the initial AquAlign™ treatment on delivered a grade level higher RFV.

Cut 3

Due to a hard frost warning the 3rd cutting was done only 35 days after the second cut on September 27. Because the 2nd cut had been delayed so severely, the stand for the 3rd cut was only 12-18 inches high at the time of this cut: Control @ 1⁄4 - 1⁄2% bloom, Test 2 @ 1⁄2% bloom.

Tissue samples were taken with the following results:

Control: RFV 251Test 2: RFV 255

Relative Forage Quality 286Relative Forage Quality 292

Both results exceed the USDA chart for RFV which we believe is a tribute to the client’s farming practices, yet the AquAlign™ treated alfalfa maintained a higher result. The client’s review of his 2013 season was that despite the unusual weather, which mitigated any concerns over the reduced irrigation water quota, he had a bumper crop. With both a higher yield and the higher RFV he has been able to charge $100/per ton more than the going rate for alfalfa. Market demand for his high quality organic alfalfa was very high.

Conclusion:

In each of the 3 cuttings, the AquAlign™ treated alfalfa out-performed the Control. Our Customer’s ultimate goal is to get a 4th crop off. With the advanced bloom characteristics of the AquAlign™ treated plants, careful timing on the cutting schedule, and weather permitting, we believe this goal to be attainable.

The TE AquAlign Systems team would also like to take the opportunity to thank the owner of K-C Farms. His dedication to organic farming methods, professional management techniques, willingness to share information and support of open dialogue has made working with him both a pleasure and a privilege!

For further information on either this or other AquAlign™ applications, we can be reached by phone at:

Canada : (905) 833.0163 USA : (480) 336.2782 Email : insight@te-aqualign.com